When problems occur in life or in business, it’s tempting to focus on symptoms: What went wrong? Who is responsible? How do we stop the immediate pain? But unless we investigate more deeply, we often end up treating the surface while the underlying issue continues to grow.

This is where Root Cause Analysis (RCA) comes in. RCA is a structured method used to uncover the fundamental reason why a problem occurred. It’s not just about putting out fires—it’s about finding out why the fire started in the first place.

What is Root Cause Analysis?

Root Cause Analysis is a problem-solving framework that focuses on identifying the origin of a problem. Instead of merely addressing the effects, RCA asks: Why did this happen? And why did that happen? until you reach the foundational cause.

By tracing issues to their root, organizations can prevent recurrence, reduce costs, and improve systems and performance. RCA is especially powerful in healthcare, manufacturing, engineering, IT, and any setting where quality, safety, and reliability are priorities.

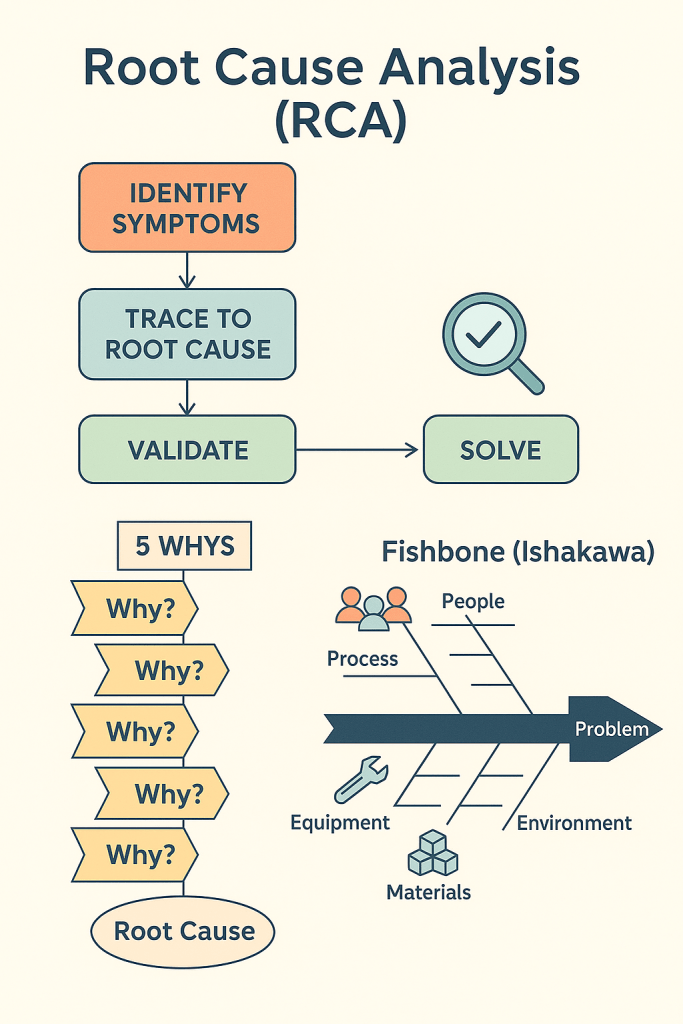

The four fundamental steps of RCA

1. Identify the symptoms

This means observing and documenting what went wrong. What are the visible indicators? What has stopped working or is performing poorly?

2. Trace symptoms back to the root cause

This is where the core of RCA lies. It requires analysis tools to ask deeper questions and uncover underlying patterns. The goal is to go beyond immediate causes and uncover the «cause of the cause.»

3. Validate the root cause

Not all suspected root causes are the real ones. It’s critical to confirm that solving the root cause will actually prevent the problem from happening again.

4. Develop and implement solutions

Once the root cause is identified and validated, you design corrective actions. These should be specific, measurable, and actionable.

Tools used in RCA

1. The 5 whys technique

This method involves asking «why?» repeatedly until the root cause is revealed. Typically, five iterations is enough, but the number may vary.

Example: A machine stops functioning.

- Why did the machine stop? (Because it overheated.)

- Why did it overheat? (The coolant was low.)

- Why was the coolant low? (Because of a leak.)

- Why was there a leak? (A gasket wore out.)

- Why did the gasket wear out? (It was past its replacement date.)

2. Fishbone diagram (Ishikawa Diagram)

Also called a cause-and-effect diagram, this visual tool helps categorize possible causes of problems under headings like People, Process, Equipment, Materials, Environment, and Management.

3. Pareto analysis

This uses the 80/20 rule to identify the most significant issues contributing to the problem. It helps prioritize efforts based on impact.

When should you use RCA?

- When issues keep recurring despite repeated fixes

- When a single incident leads to large losses or high risks

- To improve processes and reduce waste

- When you’re focused on long-term solutions, not just quick fixes

RCA is especially useful when data is available and there’s time for analysis. It’s not the best tool for emergencies or vague, undefined problems.

Common mistakes in RCA

- Stopping at symptoms: Failing to go deep enough leaves problems unsolved.

- Blaming people instead of processes: RCA is not about assigning fault—it’s about improvement.

- Jumping to conclusions: Assumptions can derail the process; always validate findings.

- Lack of follow-through: Finding the root cause is only valuable if you implement and monitor solutions.

Case study: RCA in action

Scenario: A hospital experiences several medication errors in a week.

Step 1: Identify the symptoms: Multiple patients received incorrect dosages.

Step 2: Trace back: Investigation showed that errors occurred during transcription of doctor’s orders.

Step 3: Validate: Reviewing systems showed nurses were copying prescriptions manually from unclear handwriting.

Step 4: Solve: The hospital adopted a computerized order system with mandatory digital checks. The error rate dropped dramatically.

Best practices for successful RCA

- Involve a cross-functional team

- Use real data and evidence

- Be patient and thorough

- Document every step

- Focus on processes, not people

- Monitor implemented solutions over time

Solving problems that stay solved

Root Cause Analysis is more than just a technique—it’s a mindset. Instead of rushing to fix what’s broken, it encourages us to understand what broke it, and why. That understanding leads to smarter strategies, better systems, and fewer surprises.

In a world full of quick fixes and short-term wins, RCA offers something rare: the power to solve problems that stay solved. And in that lies the path to lasting improvement.

Legg igjen en kommentar